OFFICE AREA

Office Area : Balaji Industries’ office area is tailored to meet the needs of its employees, providing a comfortable and organized workspace. The office area is equipped with ergonomic furniture, well-designed workstations, and ample natural lighting to promote productivity and well-being. Open communication and collaboration are fostered through an open layout that encourages interaction among team members.

Conference Hall : The inclusion of a conference hall equipped with modern amenities like projectors and other audio-visual equipment underlines Balaji Industries’ commitment to seamless communication and effective presentations. The conference hall is an essential space for conducting meetings, training sessions, seminars, and discussions with clients, partners, and employees. With advanced technology in place, the company can convey information clearly and efficiently.

Infrastructure : The well-established infrastructure of Balaji Industries encompasses not only its office spaces but also its production areas, warehouses, and specialized facilities like tool rooms and inspection areas. This comprehensive setup ensures that the entire manufacturing process, from design to production

TOOL ROOM

Balaji Industries demonstrates a comprehensive approach to manufacturing by incorporating in-house tool room facilities, equipped with a range of essential machinery. These facilities are vital for ensuring the maintenance, repair, and creation of molds, dies, and tooling, which are pivotal components in the production process. The presence of various machinery, including a lathe machine, bench grinder, drilling machine, and surface grinder, underscores the company’s commitment to precision and quality in its manufacturing operations.

Having in-house tool room facilities not only enhances operational efficiency but also allows Balaji Industries to respond promptly to maintenance and modification needs. This proactive approach ensures minimal disruptions in production and contributes to the company’s reputation for reliability and timely delivery.

PRESS SHOP

Balaji Industries is a well-established manufacturing company known for its extensive range of press machines. With a remarkable collection of 30 press machines, the company offers a diverse selection of both mechanical and pneumatic presses. Ranging from 10 tons to 350 tons in capacity, these press machines showcase the company’s commitment to delivering precision, efficiency, and versatility in its manufacturing operations.

Balaji Industries’ investment in these advanced press machines underscores its dedication to staying at the forefront of manufacturing technology. By incorporating both mechanical and pneumatic presses and covering a broad tonnage range, the company ensures that it can handle a diverse range of production needs, all while maintaining its reputation for delivering quality products

PROJECTION & SPOT WELDING

Balaji Industries’ investment in in-house projection machines and spotting machines reflects its dedication to precision, efficiency, and technological advancement. The capacity specifications of these machines showcase the company’s ability to handle a variety of projects while maintaining high levels of accuracy. These machines underscore Balaji Industries’ commitment to delivering top-quality manufacturing solutions to its clients and position the company as a reliable partner for industries with exacting standards.

Balaji Industries has invested in spotting machines with capacities of 50 kVA and 75 kVA. The projection machines, with a capacity of 15 AMP each and also three CO2 welding machines in-house, each with a substantial capacity of 400 amps, Balaji Industries showcases its dedication to meeting varying welding needs. The 400-amp capacity indicates the machines’ capability to handle both heavy-duty welding tasks, such as joining thick metal sections, and finer tasks that require delicate control.

SHEARING ARENA

Balaji Industries takes pride in its advanced in-house shearing machine, equipped with impressive capacities of 1500x6mm and 1000x3mm. This state-of-the-art shearing machine reflects the company’s dedication to precision metal cutting and its commitment to providing top-notch manufacturing services.

The larger cutting capacity of 1500x6mm indicates that the machine can efficiently cut sheets of metal up to 1500 millimeters in length and 6 millimeters in thickness. This capability is crucial for handling thicker metal sheets, enabling Balaji Industries to effectively work with a wide range of materials, from mild steel to stainless steel and beyond. This versatility is particularly advantageous for industries with diverse metal fabrication requirements.

SEPARATE INSPECTION AREA

Balaji Industries demonstrates its unwavering commitment to quality and precision by establishing a dedicated inspection area for its final products. This separate space is equipped with a comprehensive range of inspection equipment and facilities, ensuring that every product leaving the facility meets stringent quality standards and customer specifications.

The establishment of a separate inspection area underscores Balaji Industries’ dedication to maintaining the highest levels of product quality. By creating a distinct space for inspection, the company can conduct thorough assessments without any interference from the production process. This separation helps prevent any potential contamination, errors, or bias that might arise if inspection were performed on the production floor.

The presence of a variety of inspection equipment and facilities within this area speaks to Balaji Industries’ commitment to comprehensive quality control

SPM & COLD FORGING AREA

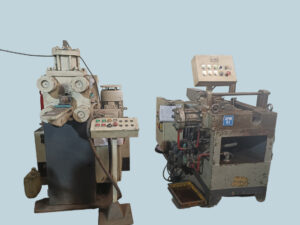

Balaji Industries proudly boasts its in-house cold forging capabilities with a set of three dedicated cold forging machines. This state-of-the-art technology underscores the company’s commitment to advanced manufacturing processes and the ability to offer high-quality products to its clients.

Cold forging is a metal forming process that involves shaping metal at room temperature through compressive forces. This method is particularly advantageous for producing complex, high-strength components with excellent surface finish and dimensional accuracy. The inclusion of three cold forging machines within the company’s facilities further highlights Balaji Industries’ dedication to precision and efficiency in its manufacturing operations.